Quick Wattage Requirement Calculation for Heated Platen or Block

Quick Wattage Requirement Calculation for Heated Platen or Block

Selecting the right electric heater and determining the wattage needed for a heated platen (hot plate) or metal block can seem overwhelming at first. There are many variables to consider and it’s easy to feel unsure where to start. That’s where a simple, reliable quick-sizing guide can make all the difference.

This guide will walk you through a straightforward method to estimate your heating requirements with confidence, even if you’re just beginning to explore electric process heating. Whether you’re designing a prototype, budgeting for a new project, or trying to improve efficiency in your existing setup, this quick calculation will help you get on the right path.

The following information is required before you begin:

- What is the material of the platen?

- What is the weight of the platen in pounds (lbs)?

- What is the starting temperature? (Typically ambient, around 70°F.)

- What is the desired final temperature?

- How much time do you have to reach that temperature?

Note: For best results, it’s assumed that the platen is insulated from additional metal contact using a rigid insulation board on all sides. Proper insulation minimizes natural heat loss and increases the accuracy of this quick calculation.

Example

You want to heat a block of steel from 70°F to 500°F in 30 minutes. The block weighs 200 lbs. What is the estimated wattage requirement?

Quick Calculation:

KW = [Weight × Cp × (Tf – Ti)] / [3412 Btu/KW × t]

Where:

Weight = 200 lbs

Cp = 0.12 Btu/lb/°F (specific heat of mild steel)

Tf = 500°F (final temperature)

Ti = 70°F (initial temperature)

t = 0.5 hours (30 minutes = ½ hour)

KW = [200 × 0.12 × (500 – 70)] / [3412 × 0.5] = 10,320 / 1706 = 6 KW

Add a 20% engineering safety factor:

6 KW × 1.2 = 7.2 KW

The estimated wattage requirement to heat the block to 500°F in 30 minutes is 7.2 KW.

Heater Selection

You will need to select a heater (or multiple heaters) with a total combined wattage equal to 7.2KW. The heater(s) physical size should be chosen to minimize hot or cold spots within the platen.

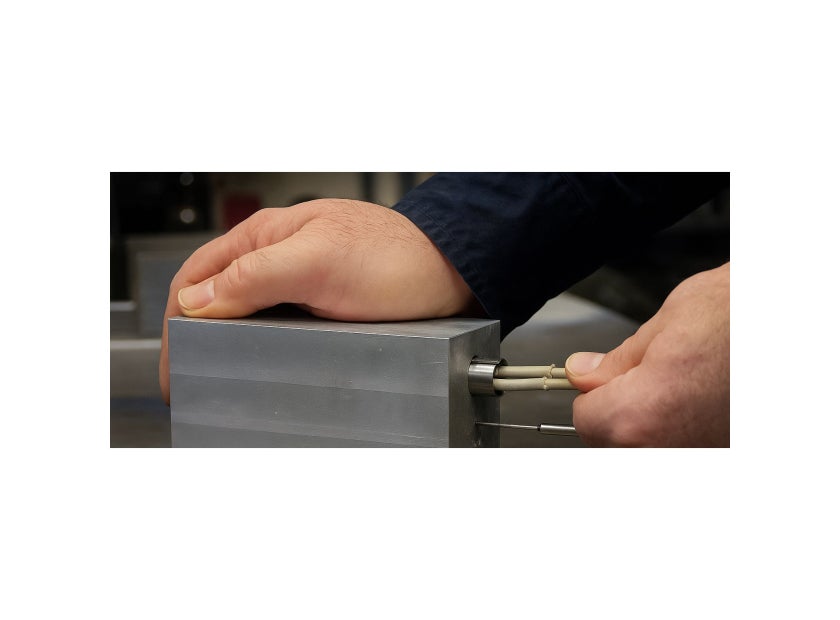

There are several types of electric heaters that can be used to heat a metal platen or block, such as cartridge heaters, metal-sheath tubular heaters, strip heaters, and flexible silicone rubber heaters. Among these, cartridge heaters are by far the most popular and efficient for platen heating applications.

Of all the cartridge heaters available, the Dalton Watt-Flex® Split Sheath Cartridge Heater stands out as the top choice for performance, efficiency, and longevity. Click here to learn more about the advantages of the Dalton heater.

Do you need help with your application?

If you’re unsure where to begin or need help refining your design, we’re here to guide you. At Mor Electric Heating, we bring decades of experience in process heating and application design. Whether your project is still on the drawing board or already in motion, our knowledgeable team can help you size your heater correctly and select the best product for long-term reliability and performance.

Reach out to us by phone or email — we’re always happy to answer your questions, share our expertise, and help you find the most efficient heating solution for your application.