Roofs with inadequate ventilation can ice up in snowy winter conditions. This can lead to ice dams at the roofs edge which prevents the melt water from the upper section of the roof from flowing off the roof. The melt water then collects at the ice dam and leaks under the shingles causing extensive water damage within the interior of the home or building and can damage a roof’s shingles. Heat trace cable provides an effective, economical method of preventing ice dams from forming on roofs and in the gutters.

At Mor Electric Heating we are experts in the field of using heat cable for ice dam prevention. We are very familiar with the wide range of heating cable available and we offer only the best available with our name on it, because we believe that if you are going to the effort of installing cable on a roof, it should last a long time! There are several manufacturers who make very high quality heat cable and they have been doing so for decades. We have focused on and partnered only with these manufacturers to provide our customers with the very best quality product at the lowest price possible. Our MOR-HEAT-TRACE product is made from 16 AWG nickel-coated copper bus wires which is larger than some other cables that use 18 AWG wire. We offer our commercial grade Heating Cables along with Power Connection Kits, End Seals, Roof Clips, Downspout Hangers and Control Panels/Thermostats.

Self-regulating Heating cable (also known as Heat tape or Heat trace) has a conductive core between two bus wires. This core becomes more conductive as ambient conditions get colder and the heating cable increases wattage in response to the cold (the number of electrical paths through the core increases and more heat is produced). This feature makes it ideal for keeping roofs and gutters clear of ice formations. The cable decreases its power output (watts), in warmer conditions, when the core becomes less conductive but the cable will not turn itself completely on or off. For this reason a controller or thermostat is used. Heating cable keeps gutters flowing (complete melting of all ice and snow on the roof and gutter is not necessary) for effective removal of melted snow and ice. The cable is available in either 120V or 240V and is sold by-the-foot, and is meant to be cut-to-length by the installer on the jobsite.

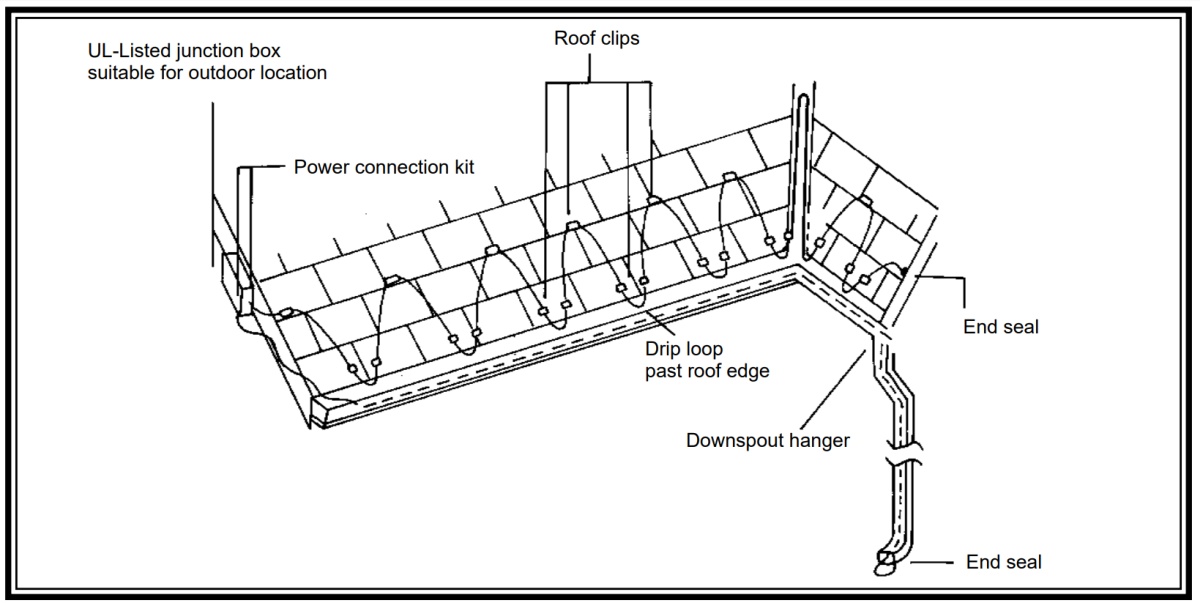

Mor Electric Heating will help design a Roof and Gutter Deicing Cable system to prevent ice dams from forming on roofs and gutters of residential homes and commercial buildings to prevent building damage. Ice dams can cause water ingress into a roof, physical damage to the structure, or a safety hazard due to ice falling onto unexpected pedestrians below. Eliminating ice dams involves laying the heat trace cables directly in gutters and downpipes, and typically also installing on the roof in a zigzag pattern. The cable is installed running over the edge of the roof line, with a "drip loop" that hangs down or is even connected to the cable in the gutter with a metal spacer, which provides a water pathway to get off the roof. The heating cable must extend into the gutter in order to prevent an ice dam that would keep the water from flowing off the roof. Self-regulating cable is typically installed along with a thermostat or control that can measure both temperature and moisture, however a simple on/off switch can be sufficient. Controls provide maximum energy efficiency because the system operates only when necessary and the cable automatically adjusts its power output to compensate for temperature variations.

Design and Installation Guidelines for Roof and Gutter Applications

Preparation

1. Verify that you are using the correct heating cable and components.

- Heating cable: 2806-11R (120 Volt) or 2806-21R (208, 240, 277 volt) (CSA Certified Roof De-Icing when used with associated kits and installed per manufacturer's instructions.)

- Power connection kit with (2) End seals: 1548-40R6P

- Roof clips: 1548-40RGC

- Downspout hanger: 1548-40RGH

2. Visually inspect components for in-transit or handling damage and perform continuity and insulation resistance (megger) tests on the heating cable.

Installation

Roof Cable Spacing and Height

1. Install components in accordance with roof and gutter component installation instructions.

2. Spacing:

Height: The Heating Cable should extend high enough up the roof to extend over onto the heated part of the building.

3. Roof-edge heating cable usage chart (does not include heating cable that will be run in the gutter and downspouts):

| Eve overhang | Feet of heating cable (per foot of roof edge) |

| 12" | 1' 6" |

| 24" | 2' 6" |

| 36" | 3' 6" |

| 48" | 4' 6" |

4. Using the roof clips, make sure the heating cable forms a drip loop at the roof edge, which extends past the roof edge, forming a drainage path off the roof.

5. Install downspout hangers above all downspouts, to help support the heating cable in those locations.

6. Extend the heating cable past the bottom of the downspouts just far enough to form a small drip loop. End seals at these locations should be tucked back up inside the downspout.

7. Tees and splices are made by using the power connection kits.

Testing Before Operation

1. After all components have been installed, but prior to hookup of power wires to heating cable bus wires, perform an insulation resistance (megger) test using a 2500 VDC megger. Reading should be at least 20 megohms.

Notes

1. Section 426-53 of the National Electric Code requires ground fault protection for all electric de-icing and snow melting applications. This ground fault protection must be at a level of protection greater than that which is provided by a standard circuit breaker. Since a 5 ma trip GFI may result in a nuisance trip, a trip level of 30 ma is recommended.

2. Part 1, Section 10 of the Canadian Electrical Code requires grounded metal structures used for support or on which the cable is installed. Do not install heater closer than 13 mm to any exposed combustible surface.

3. Install cable at -40oC or above using a minimum bend radius of 1/4 inch.

4. Some roof slopes may require the use of a snow/ice fence to prevent damage to the heating cable from snow and ice slides.

5. For gutters wider than 6 inches, use two runs of heating cable in the gutter.

Warning - the contents of the component kit must be installed correctly to ensure proper operation and to prevent shock or fire. Read these important warnings and carefully follow all the installation instructions.

• To minimize the danger of fire from sustained electrical arcing if the heating cable is damaged or improperly installed, use a ground fault protection device. Arcing may not be stopped by conventional circuit breakers.

• Component approvals and performance are based on the use of specified parts only. Do not substitute parts or use vinyl electrical tape.

• The black heating-cable core is conductive and can short. It must be properly insulated and kept dry.

• Bus wires will short if they contact each other. Keep bus wires separated.

• Heat-damaged components can short. Use a heat gun or a torch with a soft yellow low-heat flame; not a blue focused flame. Keep the flame moving to avoid overheating, blistering, or charring the heat-shrink tubes. Avoid heating other components. Replace any damaged parts.

• Leave installation instructions with the user for future reference.